We use hard wood to avoid warping and insure that the screws that hold the frame together are not pulled out with the plaster tension stainless steel screws are preferred and will.

Wedging board ceramics definition.

Having a dedicated space that won t allow for sticking of wet or leather hard clay is a good idea.

The one you will learn today is called rams head wedging.

The simplest wedging surface is a piece of canvas.

Other possibilities are concrete granite masonite concrete board and hardibacker board.

Wedging table wood frame.

There are a few ways to wedge clay.

For our wedging or clay drying tables we built a wooden frame 3 4 hard wood 2 2 1 2 deep with a bottom made out of 1 2 plywood.

Prep your clay for the pottery wheel on the xiem x board wedging board.

Continue to rotate the clay in a rectangular shape and slap it down 5 to 7 times to compress it together.

In the wedging process clay is repeatedly kneaded on a porous surface to draw some of the water out while distributing the moisture evenly eliminating hard spots in the clay.

What is wedgingwedging prepares the clay for optimal use.

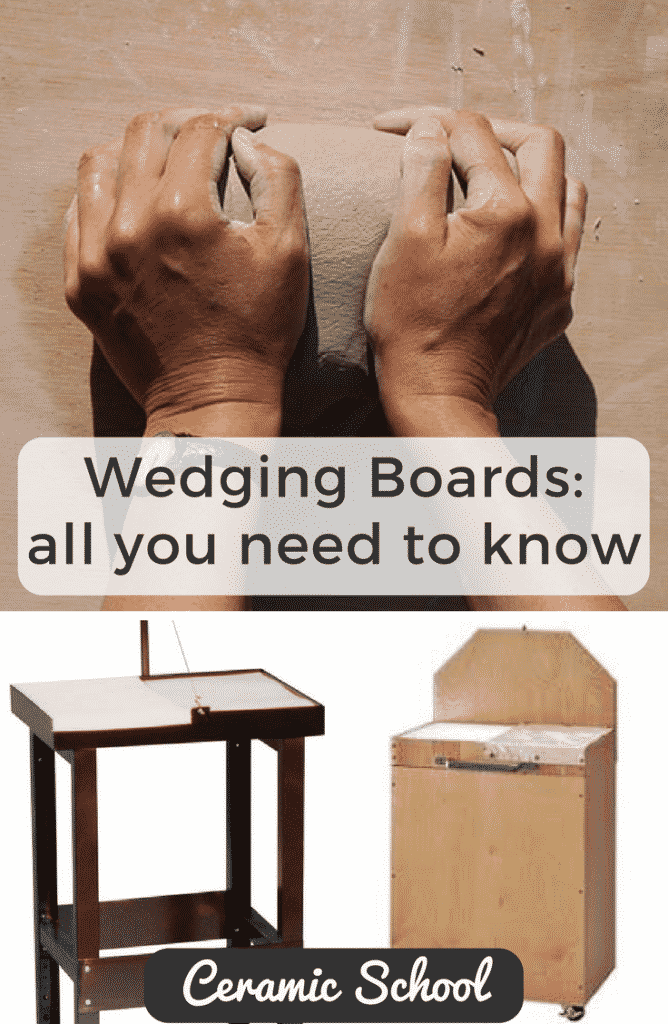

These large boards allow you to wedge your clay before throwing it on the pottery wheel there are many different options a potter can choose from when it comes to wedging boards and your personal choice mainly depends on what features you are looking for in your wedging board.

One essential tool that everyone should have in a potters studio are wedging boards.

Ok i get it now how do i make it.

Some are more expensive than others.

A wedging board is the perfect place to apply handles or alter your wheel thrown pieces.

Commercial wedging boards are available online.

You will want to cut the clay in half at least 10 times and 25 times or more if it s recycled clay.

The x board is easily portable so you can work with clay anywhere you want.

In the process air bubbles are forced out of the clay ensuring that these bubbles will not heat and cause.

Its canvas surface is a great alternative to plaster.

A wedge of clay is often set up to work on a pottery wheel.

Every potter needs a surface to wedge clay on and there are many different types.

It has a galvanized steel handle and a durable non skid rubber base.

The general idea includes throwing down the clay and rolling it into a tight spiral with a sort.